Client Case Study

The Challenge

While performing scheduled maintenance on downhole production equipment in a US land well, a large independent operator encountered a section of stuck tubing. After numerous remedial milling and cutting operations, the operator was unable to pull a section or determine the cause of the sticking. A decision was made to shut in the well.

A year after shutting the well, the operator needed to diagnose the current condition of the fish and where it was located within the wellbore. They wanted a quick and reliable solution so that they could confidently proceed with fishing the tubing and avoid rising intervention costs.

Our Solution

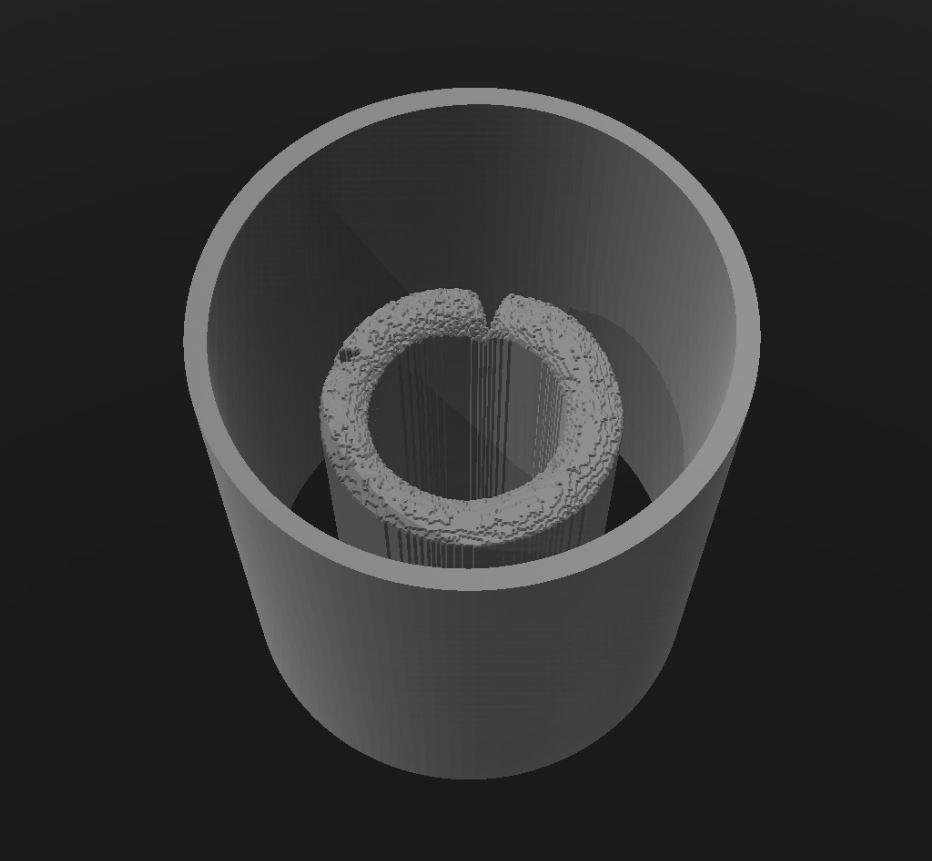

Visuray ran the VR90 downhole X-ray diagnostic service in the client well to evaluate the condition of the tubing. Multiple areas were inspected to both measure the current dimensions of the tubing and assess its orientation in the casing. The resulting 3D reconstructions of the tubing top showed extensive concave milling damage that reduced the outer diameter. In addition, the milling had squeezed the inner diameter such that it was preventing the onsite fishing tools from passing into the tubing.

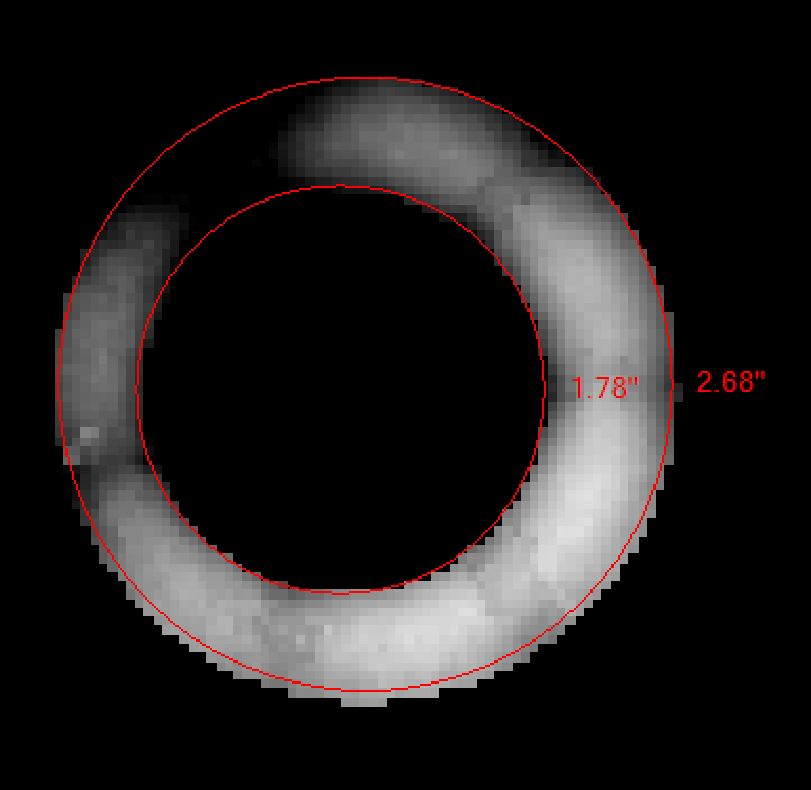

The 2D X-ray image on the top right showed that the outer diameter of the tubing had been reduced from the original 2.875 in to 2.68 in as a result of the concave milling. The inner diameter of 1.78in was also smaller than before milling.

The illustration on the bottom right showed the tubing to be fairly centered in the casing, with no discernable angle of orientation, nor any pinching or collapsing of the surrounding casing that would hav prevented it from being latched with an overshot.

Client Benefit

After extensive intervention activities and time spent on this well, the operator required a quick and reliable diagnosis of the current condition of the tubing. As the well had been abandoned for more than a year, the opaque and debris-filled well fluid made the VR90 service the best solution. The VR90 X-ray diagnosis provided the operator with the precise size and location of the tubing top, which allowed them to confidently develop an appropriate intervention strategy.

View Client Case Study PDF