Evaluative Case Study

During drilling, drill pipe often gets stuck in the well. Once the free portion has been retrieved, a fishing operation follows to retrieve the stuck portion. Ideally, this requires inspection of the top of the stuck drill pipe. For this, video cameras are impracticable because drilling mud is opaque and it is usually too expensive or even impossible to flush the well with clean water.

The X-rays produced by Visuray’s VR90, however, can penetrate even the heaviest and most opaque drilling muds, providing information about the location and dimensions of the top of the stuck drill pipe.

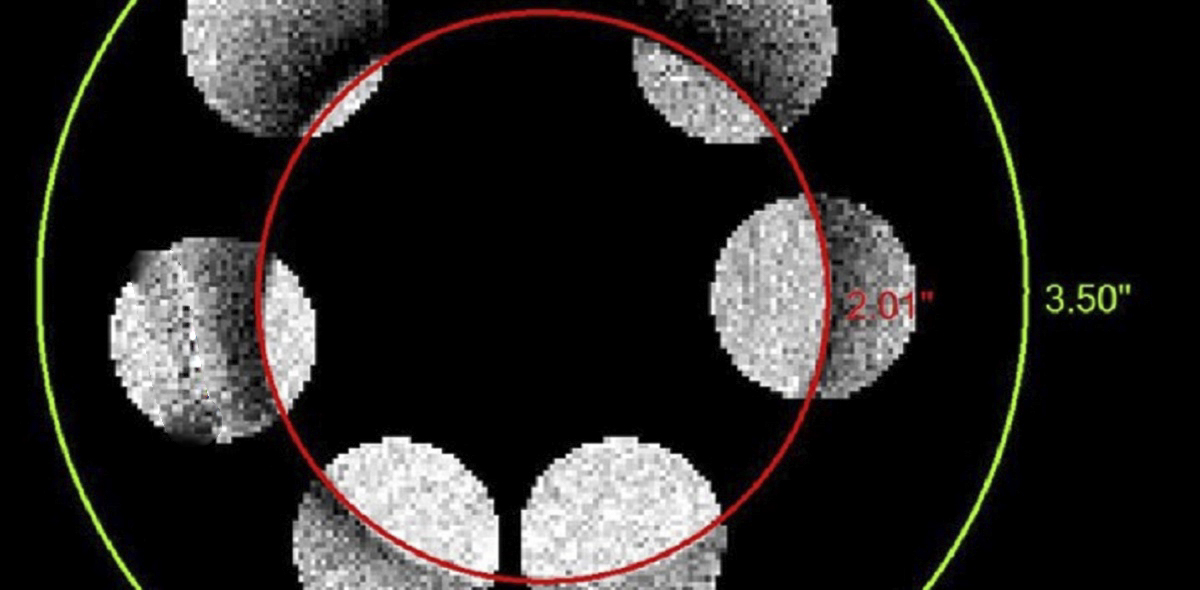

The image (top) of a 2-in ID/3.5-in OD section of drill pipe placed in a heavy mud (approximately 19 ppg) was obtained at Visuray’s test facilities. The ID of the drill pipe (marked with the red circle) is clearly visible, but the OD (position estimated by the green circle) is out of the tool’s field-of-view. Combined with the VR90’s depth readings provided by integrated gamma-ray and CCL units and the tool’s high-side indicator, an operator now has the ability to determine the precise dimensions and position of stuck drill pipe.